Insul-Quilt Studio Liner

About Us

History

Since the 1960s, Insul-Quilt has been exclusively manufactured in Los Angeles, California, serving Hollywood film studios and beyond. Our impressive client list reads like a “who’s who” of the film industry, and we are honored to be part of a company with such a pioneering legacy. Insul-Quilt is widely recognized as the leading choice for film studio liners worldwide.

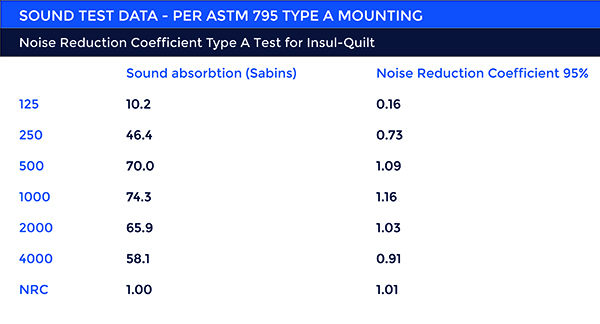

Technical Data

Salex Studio Liner Technical Document

Product Specification

The product is crafted from two 25mm layers of glass fibre with a density of 24kg/m³, featuring a foil-coated backing paper and an open-weave glass cloth face. Once stitched together, the material forms a duvet-like structure. Available in black or white as standard, custom colors can be ordered for an additional cost. Insul-Quilt also holds BS476 Class 0 Fire Certification.

Both Acoustic & Fire test certificates are available as requested.

Achieving a Noise Reduction Coefficient of 1.00 and BS476 Class O fire test.

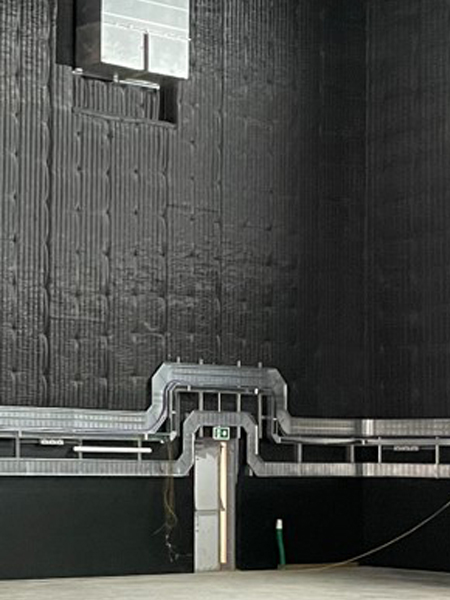

Installation

Generally when installing InsulQuilt in a new build Film Studio, the design of the wall usually includes plasterboard Soundblocker material. When using this method the InsulQuilt can be fixed directly to the Plasterboard wall with drywall screws and penny washers. Set at 600mm centres in both direction, this method is an easy fix, with the material only weighing 2.15kgs/m2. This method is easy to do and reliable to use.

When measuring product lengths consideration for turnbacks at joints should add 300mm where two rolls join together.

To ensure sound leakage is avoided a 50mm overlap between adjacent lengths must be added. This represents a 4% addition.